RoboOp365 Resource Hub

Explore the resources you need to evaluate, implement, and scale robotics with confidence.

ROI Tools

Evaluate the business case for automation with calculators designed for operators. Explore which prep tasks, if automated, deliver the highest ROI and compare the cost of hiring another cook versus adding a kitchen robot. Each tool gives you a fast, data-backed estimate. And if you’d rather talk it through, we can walk the numbers with you one-on-one.

Request an ROI WalkthroughFeatured Blogs

Featured Articles

Podcast

Episode: The ROI Comparison — Hiring a Cook vs. Kitchen Robot. Listen for practical math and benchmarks operators can use in planning.

Listen now

Get the transcript

Prefer text? Download the episode transcript to share with your team and mark up the ROI math.

Download episode transcriptAlso part of the Restaurant Operator Series — a deep dive across articles, ROI tools, and training.

Read a preview of the episode

Hiring a Cook vs. Kitchen Robots — ROI Explained

In this episode of the Restaurant Operator Series, hosts Lauren Cochran and Alex Richards unpack one of the most pivotal decisions facing operators today: whether the next dollar should go toward hiring another cook or investing in kitchen automation.

They start by examining the true “fully burdened” cost of labor — not just hourly wages but benefits, payroll taxes, recruiting, and the repetitive cost of 80% annual turnover. A single cook’s annual cost often exceeds $52,000 when those layers are added. Each resignation restarts the expensive cycle of hiring, onboarding, and training, draining both time and profitability.

Then they contrast that volatility with the fixed predictability of automation. A robot represents a capital investment rather than a recurring variable expense, capable of 80–100 hours of consistent weekly output without turnover, retraining, or fatigue. In many kitchens, one robotic unit can replace or outperform two human cooks at roughly half their combined fully burdened cost.

The hosts explore broader ripple effects: automation improves consistency by roughly 12%, reduces food waste by about 4%, and enhances safety by removing workers from high-risk, repetitive tasks. These gains translate directly to cost savings and steadier margins.

But they also emphasize revenue generation. Faster throughput, shorter wait times, and fewer abandoned guests can add up to more than $195,000 in incremental annual revenue for a 30-table operation. They highlight how shaving just 10 minutes off table turns or preventing 15 lost customers per week meaningfully improves profitability. Even dessert and drink sales rise when service moves faster and guests stay engaged.

The conversation closes with guidance for operators: start small, pilot one automation point (like a fryer or batch station), track measurable savings, and scale strategically. The goal isn’t replacing staff — it’s creating predictability, safety, and growth in an industry defined by turnover and uncertainty.

Restaurant Operator Series

Part of RoboRadar Insights, this is a deeper track for restaurants. Some Featured Articles above may come from this series. Use the links below to explore the full, restaurant-specific collection.

What’s inside

- Anchor reads: E.g. Top 10 Ways to Reduce Kitchen Labor Without Sacrificing Quality

- Business case & benchmarks: costs, time-savings, ROI tools

- Staff redeployment & training: toolkits, PDFs, and guides

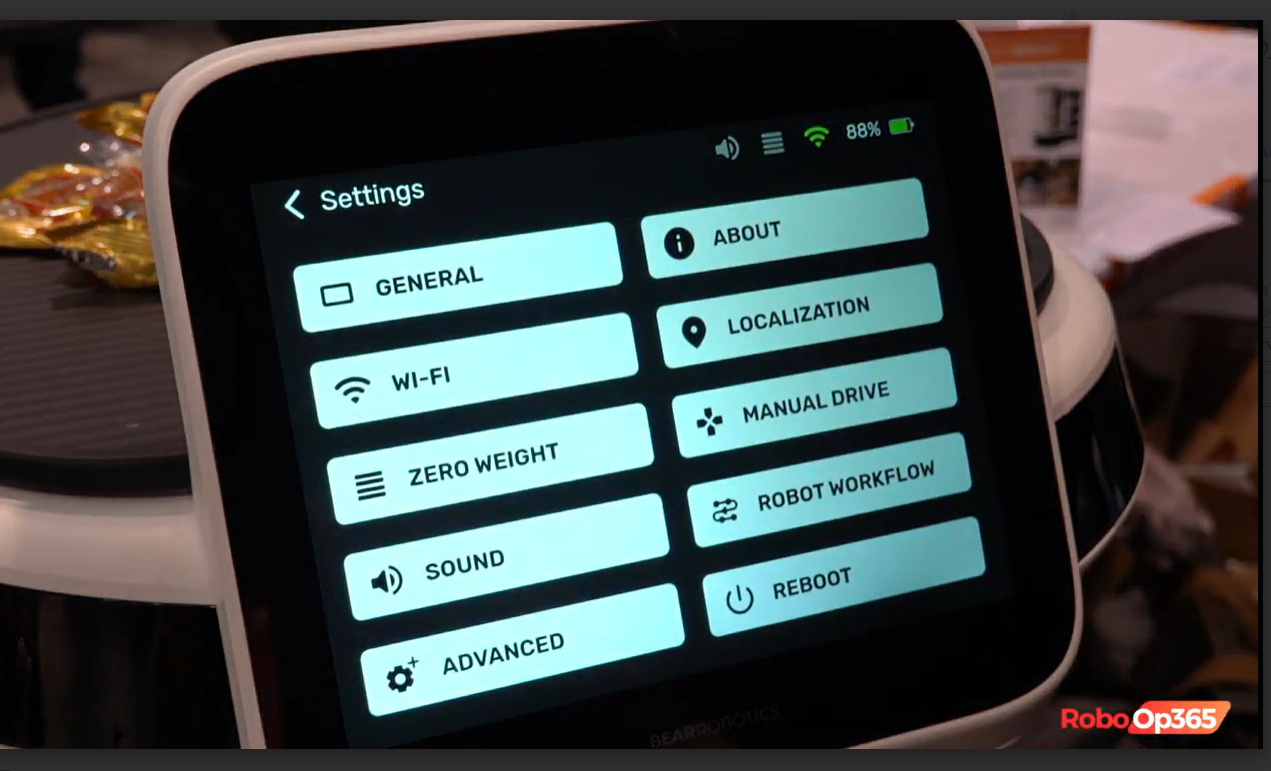

- Operational consistency: SOP checklists & tech walkthroughs

- Insight Clips: short, skimmable video takeaways

How to explore

Series Page (curated)

A guided path through Featured Articles, ROI tools, staff training, and videos, built to read in order.

Series Feed (auto-updated)

All posts from the Restaurant Operator Series—newest first. Posts link to related tools, downloads, and clips.

Note: Some Featured items above also appear in this series. This section groups all restaurant-specific content in one place.